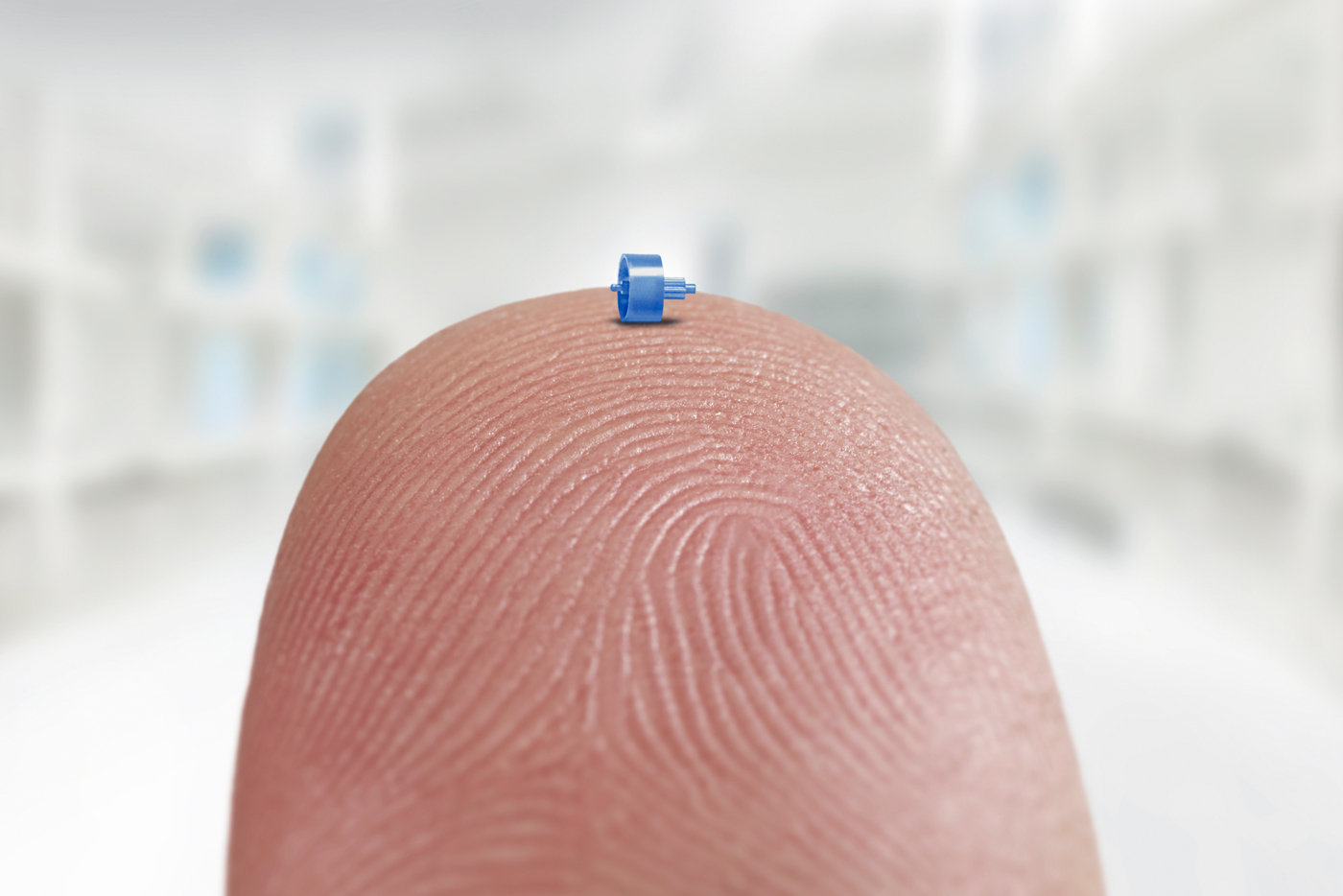

True micro-molded parts can be smaller than the pellet of resin used, allowing multiple parts to be made from one resin pellet. Our efficient material and tooling techniques deliver exceptional yields of 10,000 parts per pound, including the runner. While miniature parts are the next step larger in physical size, they often have micro features. Knowing how to inspect and package micro and miniature components, assures parts to specification from the molding operation to the end device.

We have experience in a wide variety of engineering grade materials such as:

- PEEK™

- Ultem®

- Bioresorbable

- Other engineered resins

The SMC Micro Molding advantage:

- Micro molded medical parts from 0.003 cubic inches (0.045 grams) and smaller

- Material yield advantage – 10,000 parts/shots per pound, including the runner

- Medical quality systems

- High and low volume manufacturing

- Project Management

- Initial design support for micro and miniature molding

- Specialized inspection methods

- Material handling for micro parts

- Integration of micro parts into full assemblies

SMC's micro molding capabilities yield 10,000 parts per pound of resin. Micro parts are considered less than 0.003 cubic inches and fall between 0.140 x 0.140 x 0.155 inches.