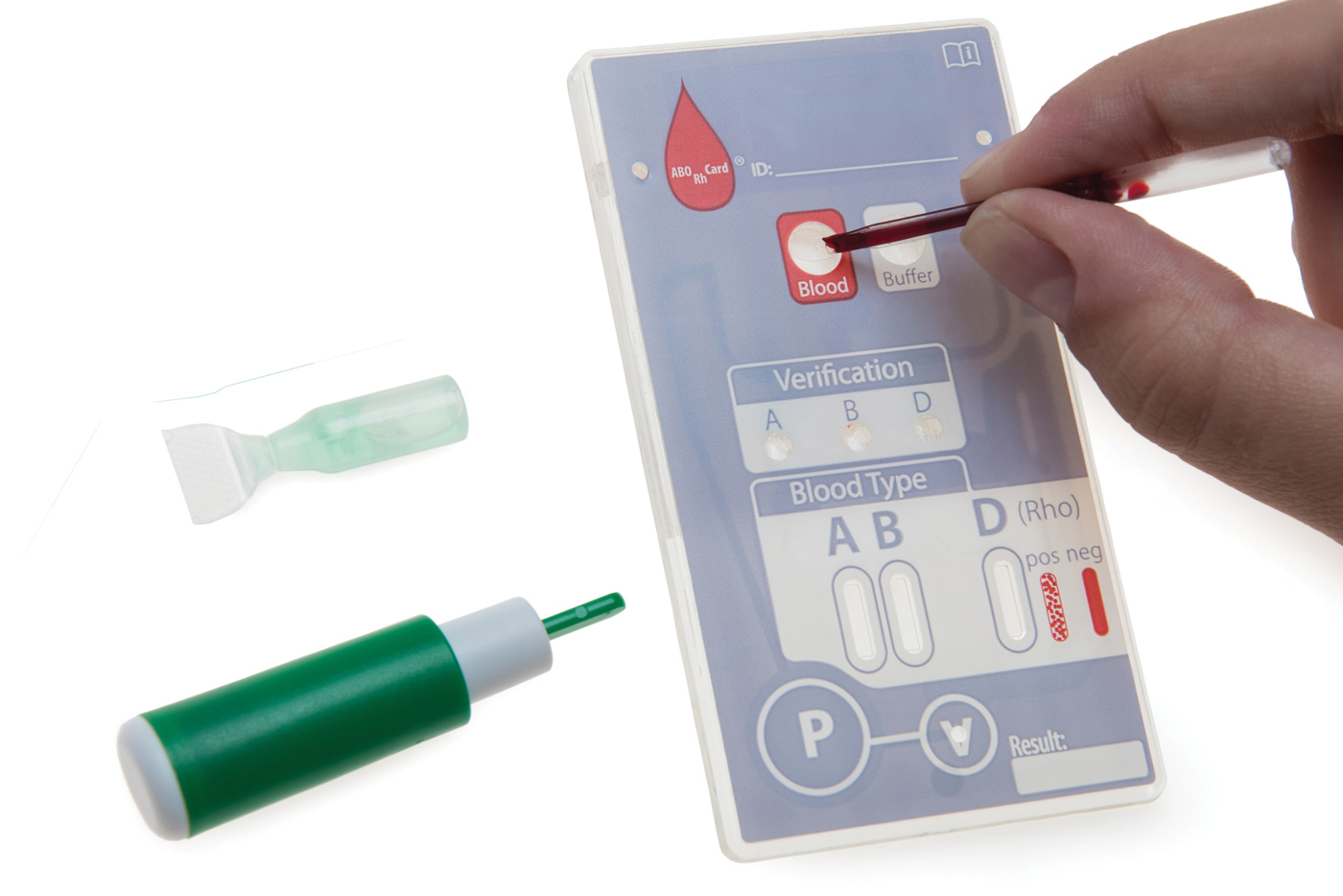

Case Study: Field Blood Typing Card

August 2, 2024

Join us at PDA Vienna – October 21-22, 2025 and PODD Boston October 27-28, 2025

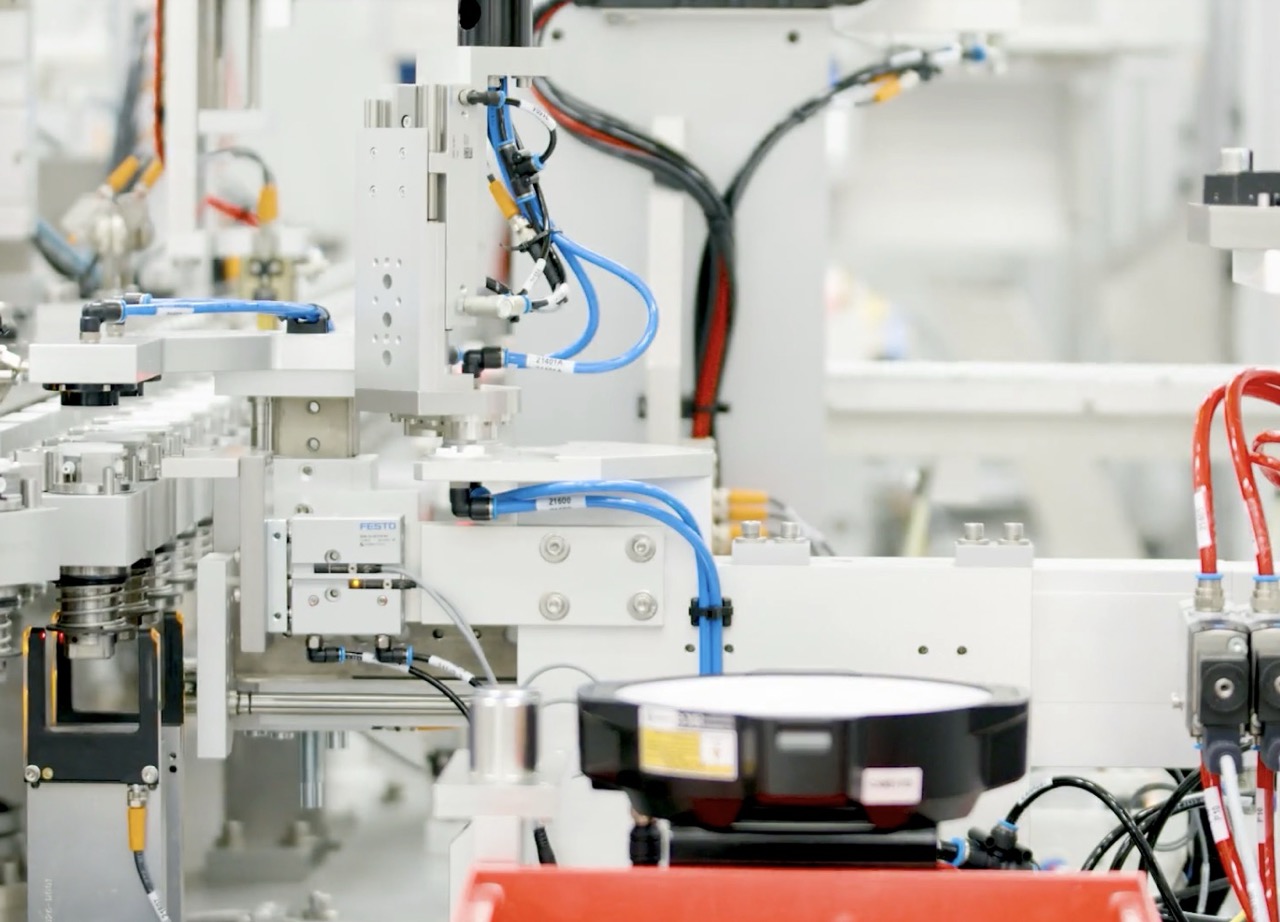

SMC Ltd. offers vertically integrated solutions for the production of combination devices, supporting programs from clinical trial builds through commercial scale.

Our capabilities span precision molding, drug-device assembly, high-speed automation, and GMP-compliant labeling and packaging. By consolidating these processes under one roof, we help reduce transfer risks and streamline supply chains. More than a contract manufacturer, SMC is a collaborative partner in your product’s life cycle.

SMC’s integrated approach combines advanced assembly, labeling, and packaging capabilities with deep regulatory expertise and precision manufacturing. From prototyping to fully automated commercial lines, we ensure every combination product meets the highest standards of quality, compliance, and patient usability.

What We Do

High-precision vision inspection systems to ensure packaging quality. Adherence to FDA regulations and current Good Manufacturing Practices (cGMP) and Quality System Regulations (QSR). Facilities certified for quality management (ISO 9001) and medical device quality management (ISO 13485).

WORKING WITH US

Whether scaling up for global commercialization or preparing for pivotal trials, we provide the expertise, infrastructure, and reliability you need to bring life-saving therapies to patients faster and safer.

As strategic partners for customers like you, our purpose is to make sure that your innovations are manufactured efficiently, at scale, and that they go to market rapidly, in full compliance with quality and regulatory standards. To make sure that plans are executable and execution goes as planned, we maintain close control over manufacturing with our extensive in-house capabilities. Our best-in-class facilities are ISO 13485, FDA registered, Part 4 compliant, Bio Level 2 certified and cGMP/QSR compliant. As a privately owned, global company, we pride ourselves on the ability to pivot quickly to meet your needs.

Safe and efficient handling of chemicals and fluids.

High-precision vision inspection systems to ensure packaging quality.

Cutting-edge equipment for form, fill, and seal operations.

Tray sealing, pouch coding, opening, and vacuum sealing for secure packaging.

Our contract manufacturing capabilities, focused on single-use and disposable medical devices, include innovative autoinjector platforms designed for subcutaneous or intramuscular injection. These platforms can be customized to your drug formulation.