Mini and Micro Molding for Medical Parts and Devices

PRECISE COMPONENTS AT ANY SIZE

Medical micro molding expertise for complex, miniature parts and assemblies.

At SMC we understand that precision matters when it comes to micro-molded medical parts.

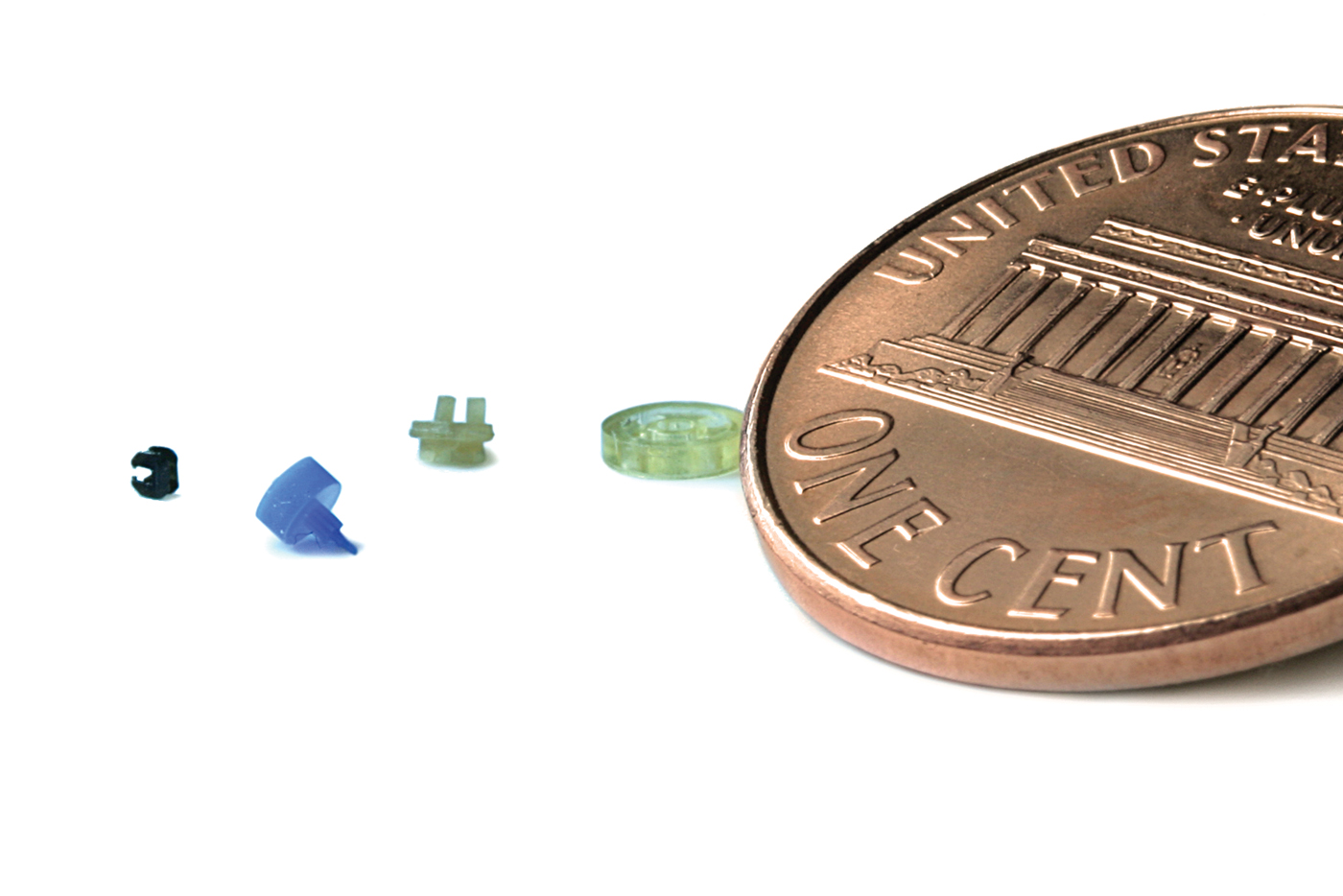

True micro-molded parts can be smaller than the pellet of resin used, allowing multiple parts to be made from one resin pellet. Our efficient material and tooling techniques deliver exceptional yields of 10,000 parts per pound, including the runner.

While miniature parts are the next step larger in physical size, they often have micro features. Knowing how to inspect and package micro and miniature components, assures parts to specification from the molding operation to the end device.

What We Do

Extensive Material Expertise for Micro and Miniature Molding

Our micro molding team works with a wide range of high-performance, engineering-grade materials to meet the demanding requirements of medical applications. This includes:

PEEK™

(Polyether Ether Ketone)

Known for exceptional strength, chemical resistance, and biocompatibility, making it ideal for high-stress medical components.

Ultem® (Polyetherimide)

Offers excellent thermal stability, high mechanical strength, and resistance to sterilization processes, perfect for reusable surgical instruments and precision housings.

Bioresorbable Materials

Designed to safely break down within the body, supporting advanced drug delivery systems, orthopedic devices, and temporary implants.

Other Engineered Resins

We regularly work with specialty polymers tailored for chemical resistance, dimensional stability, and precise performance in highly regulated environments.

Our expertise in selecting, processing, and validating these materials ensures every micro component meets strict regulatory standards, performs reliably, and integrates seamlessly into your complete assembly.

WHY SMC

The SMC Micro Molding Advantage:

We manufacture micro and miniature medical components from 0.003 cubic inches (0.045 grams) and smaller, with the ability to produce up to 10,000 parts per pound of material, including the runner.

Optimized for Quality & Yield

- Industry-leading material yield for reduced waste and lower cost per part

- Specialized material handling processes to protect micro parts throughout production

- Advanced medical quality systems to meet stringent regulatory requirements

Flexible Manufacturing Volumes

- High- and low-volume production capabilities

- Integration of micro parts into complete medical assemblies

Comprehensive Project Support

- Early-stage design assistance for micro and miniature molding

- Dedicated project management to keep timelines and budgets on track

- Specialized inspection methods tailored for micro-scale components

FEATURED CASE STUDY

Micro Mini Case Study

Discover how SMC’s precision micro molding capabilities delivered complex medical components while meeting strict quality standards and maximizing material yield and production efficiency.