U.S. Lift-and-Shift Manufacturing Transfer

Case Study: Stabilizing Production and Accelerating Continuity During a Facility Transition

Overview

SMC partnered with a medical device OEM to execute a U.S.-based lift-and-shift manufacturing transfer involving a complex, multi-component surgical device. The project required rapid stabilization of production, coordination across multiple OEM locations, and the development of new quality systems—while ensuring continuity of supply and long-term cost efficiency.

The Challenge

The customer required a manufacturing partner capable of taking full ownership of a complex finished device assembly while supporting a broader vertical integration strategy. The transition involved coordinating multiple stakeholders, suppliers, and quality requirements—all under tight timelines. Key challenges included:

- Implementing a vertical integration cost strategy for a 35+ component assembly

- Coordinating manufacturing and transition efforts across three OEM sites

- Managing the transition of 20+ suppliers and 60+ SKUs

- Creating new quality documentation and procedures to meet updated OEM requirements

- Planning for future vision systems to support automated product verification

The Solution

SMC applied its lift-and-shift expertise, assembly capabilities, and quality system infrastructure to absorb the program and stabilize production. The team worked closely with the OEM to align documentation, processes, and long-term manufacturing strategy while maintaining uninterrupted supply. SMC’s solution included:

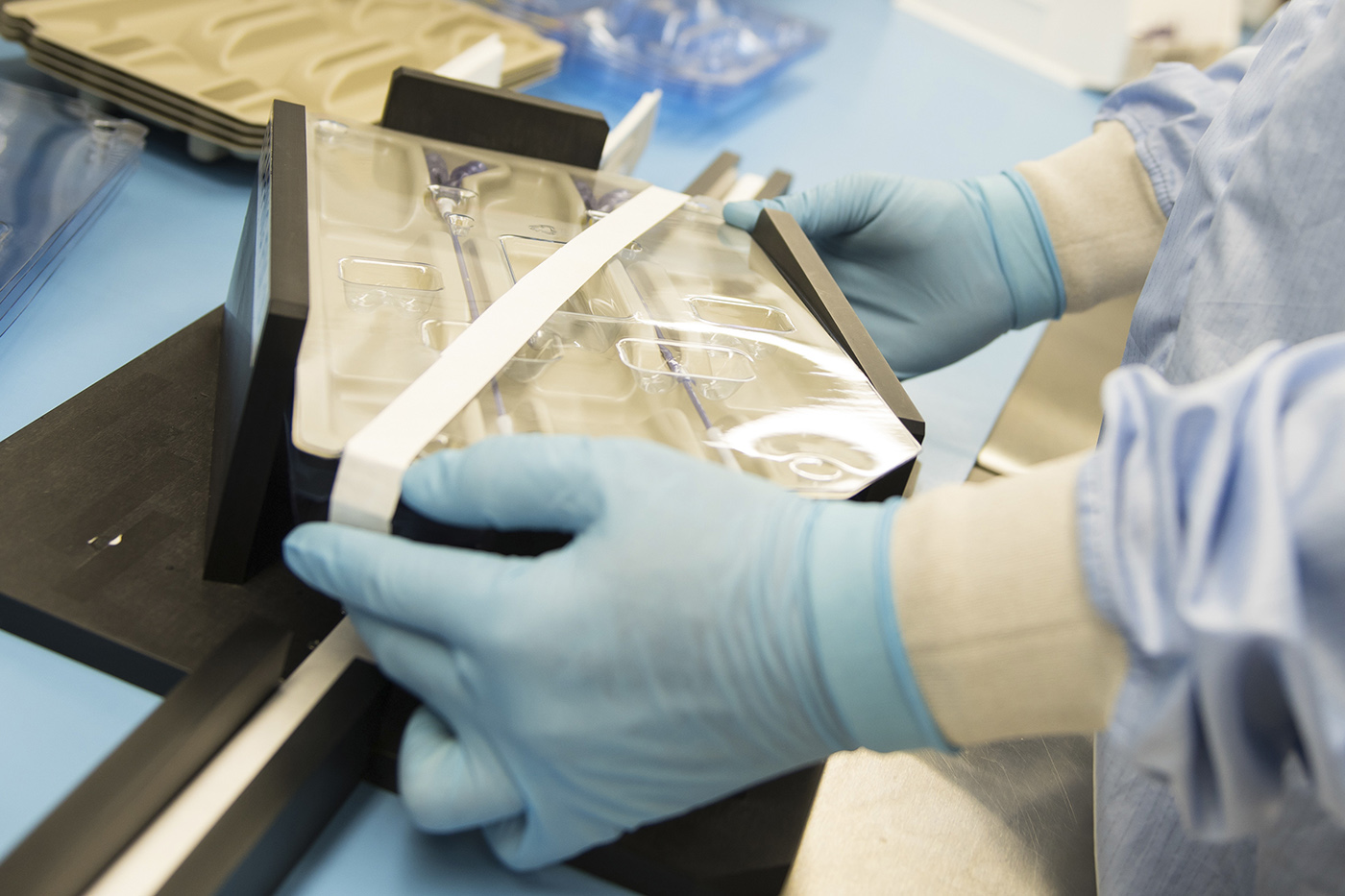

- Establishing manual and semi-automated assembly processes to support flexibility and scalability

- Taking responsibility for complete finished device assembly, including saline or water filling of the pouch

- Developing processes aligned with the OEM’s evolving quality and verification requirements

- Building a manufacturing foundation capable of supporting future automation and inspection technologies

The Results

The lift-and-shift transition resulted in a fully stabilized, end-to-end manufacturing solution with complete ownership of assembly, packaging, and downstream logistics.

- Fully assembled finished devices, 100% pressure tested

- Devices packaged in thermoformed trays and Tyvek sealed

- Products shipped to sterilization and returned to SMC for kitting with other sterile surgical products

- Completion of final end-user packaging, including labeling and instructions for use (IFU)

- A scalable, U.S.-based manufacturing solution supporting long-term supply and cost objectives