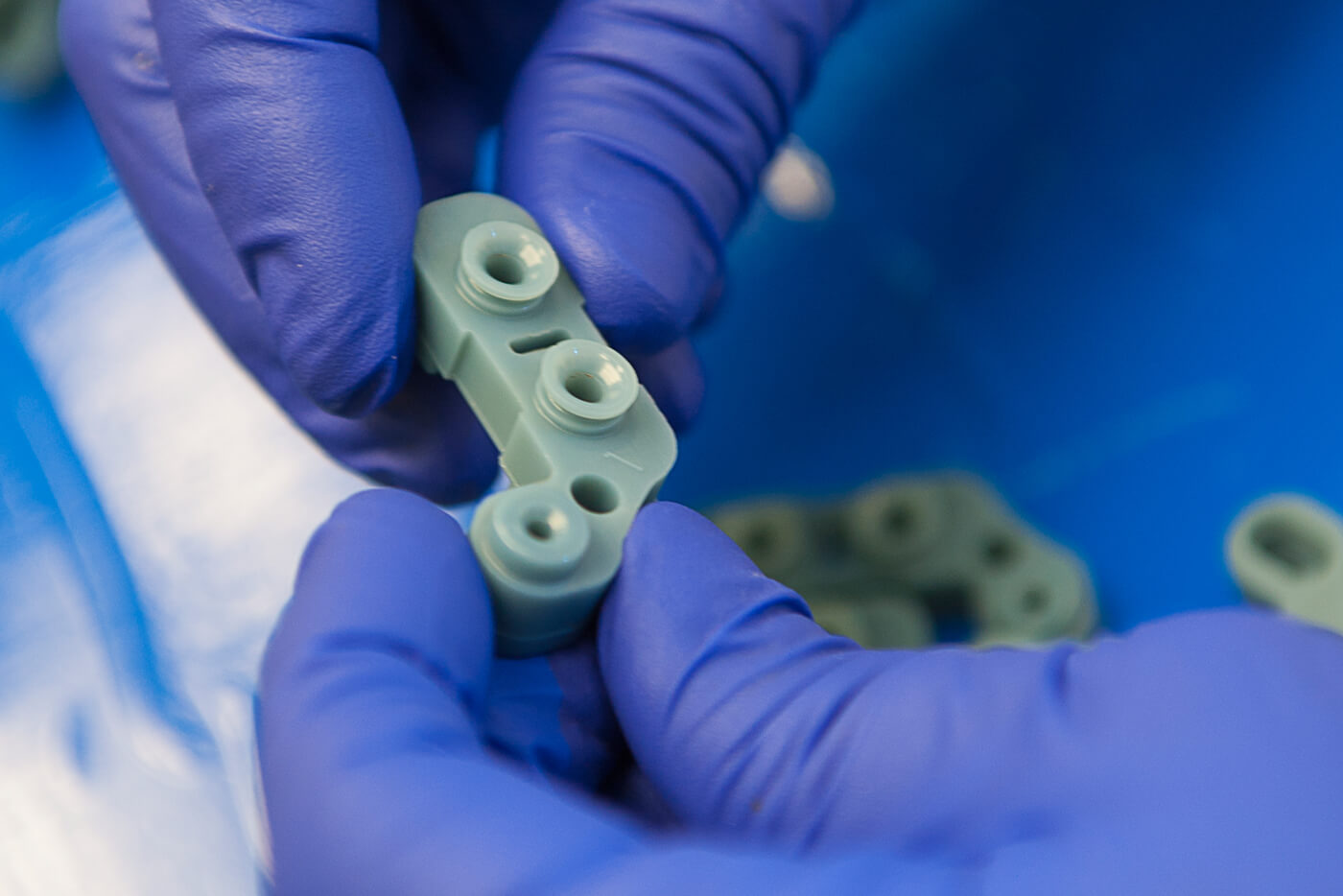

Medical Silicone Injection Molding Services

TURNKEY CAPABILITIES

When it comes to medical liquid injection molding (LIM), we can bring your program to market in the shortest time with the most predictable outcome.

At SMC Ltd., we have proven that complex silicone parts can be produced repeatedly in nearly half the lead-time as traditional silicone molding options. With capabilities that range from up-front product development through the commercialization of finished devices, we can bring your silicone program to market in the shortest time with the most predictable outcome.

What We Do

End-to-End Silicone Injection Molding Expertise for Medical & Pharma Devices

At SMC, we provide regulated companies the assurance of electronically controlling and meeting applicable FDA and International compliance requirements.

Aesthetics

- Complex, contoured geometries

- Precise color injection systems allowing custom colors and shades

- Customized aesthetics

Processes

- Design for manufacturability

- Wide variety of silicone materials including self-bonding grades

- Overmolding of thermoplastics and metals with silicone

Tooling

- In-house precision tool-making capabilities with reduced lead times

- Ultra precision through unique in-house mold making processes

Manufacturing

- Automated closed-loop systems optimizing cycle times

- In-line curing systems

- State-of-the-art machines with applied robotic and automation equipment

FEATURED CASE STUDY

Top 10 Tips for Medical Silicone Molding

Discover best practices for achieving consistent, high-quality results in silicone molding.