U.S. Lift-and-Shift Manufacturing Transfer

August 2, 2024

Join us at DCAT, New York March 23-26, 2026

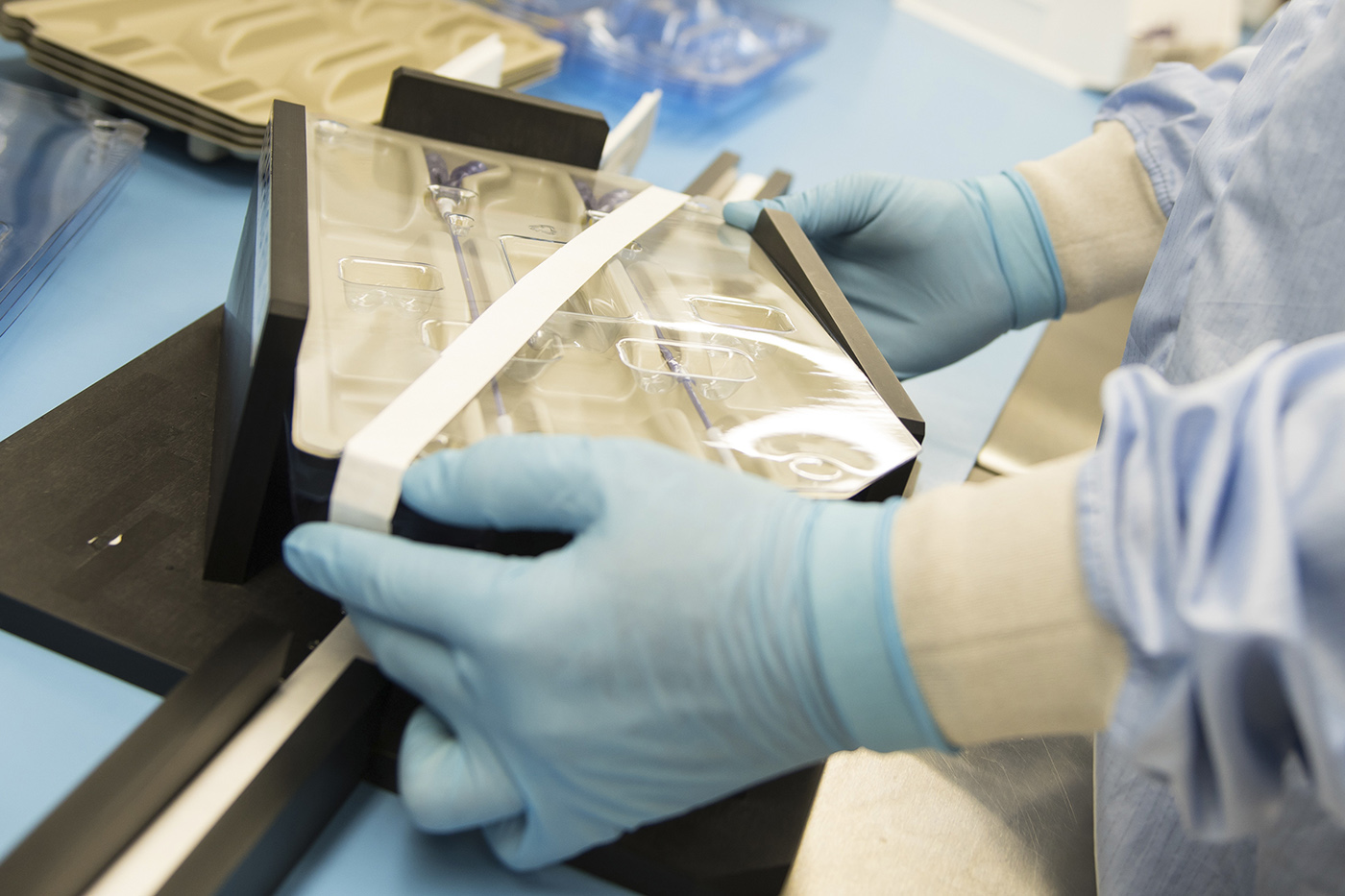

A true partner in medical device contract manufacturing has capabilities beyond molding and assembly. At SMC, our professional Supply Chain team qualifies and manages suppliers for non-molded components such as electronic components, machined and stamped specialty metals, converted materials, diagnostic fluids, chemicals and buffers, extrusions and packaging. We create resilient and sustainable global supply chains that mitigate risk, enhance speed to market, boost productivity and reduce complexity and cost.

As your complete contract manufacturing partner, we control the supply chain through the entire device lifecycle, to ensure that your requirements are met. Our supply chain strengths include not only the collective experience of our team, but also the utilization of intelligent digital systems that harness the power of AI and data streams to proactively address disruptions and improve supply chain reliability.

Your Program Manager pulls together the resources of SMC into an expert team while providing you with a single point of contact and accountability. While you always have access to all team members, the Program Manager has overall responsibility for your program and its performance, including communication, volume expectations, cost parameters and regulatory requirements. Your team will also always include a Quality Engineer. Quality goes beyond producing your product to specifications; it is a system of compliance that includes processes and documentation through every phase of the project.

A Subject Matter Expert—an engineering leader with highly specialized technology expertise—may provide experience and work alongside the Program Manager and others. This specialized expertise might include:

At SMC, supply chain management begins as a partnership. We listen, we understand your risks and we can quickly pivot from a reactive to a proactive strategy in anticipation of supply chain disruptions or other issues.

We align ourselves with significant suppliers who have a global footprint. Our strategic sourcing team reviews the financial integrity, manufacturing capabilities and quality systems of suppliers before they are considered viable partners.

Our engineers and supply chain experts continuously monitor supplier metrics to ensure the supply chain is efficient, competitive, on time, and delivers high quality and value. Our controlled process verifies that we receive a uniform product time and time again to meet required standards.

SMC Ltd. helped a large surgical device developer bring a highly complex balloon kyphoplasty device to market quickly, while improving quality. Supply chain management was an integral part of the manufacturing program.

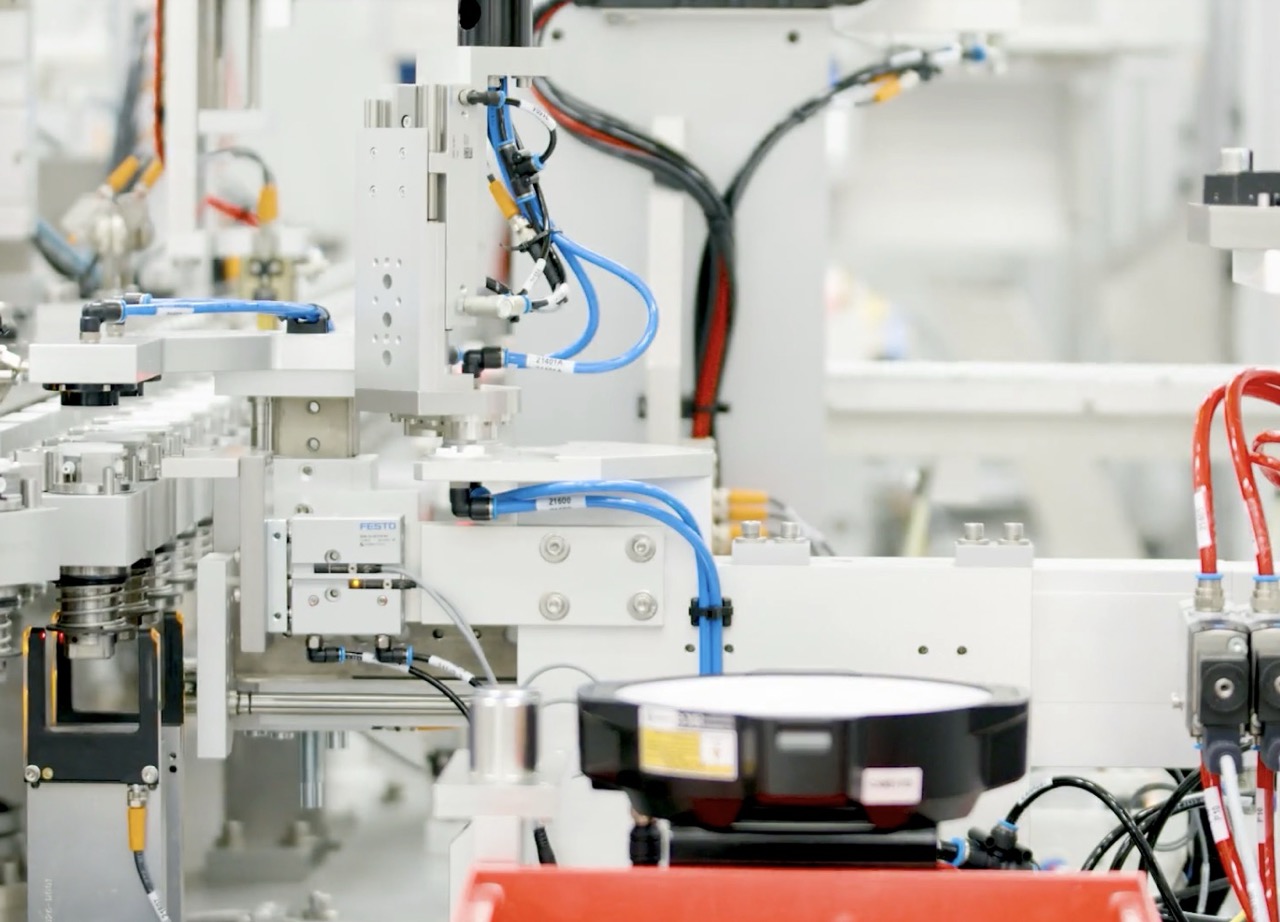

Yes, SMC is a global organization with 11 locations – United Kingdom, India, Costa Rica and 9 located in the United States (California, Ohio, Wisconsin (4), Massachusetts, North Carolina).

All SMC facilities are designed to produce high-volume medical devices, but each location has unique specialties. For example: SMC Somerset specializes in silicone manufacturing. North Carolina serves as our dedicated fill-finish location. Our facilities are strategically located to provide convenient access and support to our customers. To determine which facility is best suited for your project, we recommend reaching out to us for personalized guidance. Contact us for more information.

All of SMC’s manufacturing falls in either the Medical Device, Diagnostics, or Pharmaceutical Markets. We do not manufacture anything in other markets.

At SMC, we stand out among other CDMOs (Contract Development and Manufacturing Organizations) because of our unique approach and capabilities. Not only are we a privately held company with an actively engaged management team, but we also specialize exclusively in medical manufacturing, serving the medical device, diagnostic, and pharmaceutical markets.

Our end-to-end manufacturing solutions cover everything from design to production, including fill-finish capabilities. With subject matter experts (SMEs) available every step of the way, we ensure a seamless process tailored to your needs.

What truly sets SMC apart is our proprietary auto-injector technologies, which we offer exclusively to our customers.

At SMC, the sooner we can get involved, the better! However, we’re happy to assist at any stage of your project. Whether you’re starting with a simple concept—like a napkin sketch—or transferring a fully developed program through a lift-and-shift process, we’re here to help.

It’s always best to engage your Contract Manufacturer (CM) as early as possible during your program’s planning phase. Early collaboration allows us to partner with you effectively and thoroughly review the manufacturing aspects of your project for optimal success.

At SMC, the collaborative supply chain teams, led by our Chief Supply Chain Officer, employ best-in-class techniques to ensure customer success on a global scale. The SMC-approved supplier list includes multiple alternatives for all major commodities, providing diverse sourcing options to mitigate risk. We collaborate closely with internal stakeholders, including finance, engineering, operations, and legal teams, to ensure alignment and support for procurement strategies tailored to address customer concerns and needs. By building and nurturing strong relationships with key suppliers and partners, we leverage strategic advantages that foster innovation, enhance pricing power, and provide flexibility in production and transportation.

Key performance indicators (KPIs) are utilized to measure the effectiveness of procurement strategies and operations, driving continuous improvement in supply base processes, systems, and practices. Our approach anticipates and mitigates risks by accounting for economic, geopolitical, and environmental events that may impact procurement and supply chain operations. Additionally, we achieve buying power through a combination of concentrated spending with key suppliers, independent pricing and minimum order quantity (MOQ) negotiations, and the use of purchasing data and forecast extrapolations.

Our success in managing potential supply risk is rooted in our focused approach across several key areas. We maintain a strong core of senior technical and commercial leaders within SMC, ensuring that experienced leadership drives risk management efforts. Identifying supply risk areas and implementing mitigation strategies is a core responsibility of our senior management and their teams. To stay ahead of our customers’ capacity needs, we pre-invest in infrastructure, ensuring preparedness and adaptability. Consistent technology investments enable us to mitigate risks related to both obsolescence and security.

Additionally, we provide safety stock of both raw materials and finished goods to support our customers’ needs. Where applicable, we employ dual sourcing for critical components to enhance supply chain resilience. Lastly, site-specific business continuity plans allow us to respond quickly and effectively to unexpected events, minimizing potential disruptions.

Yes, all SMC Facilities are ISO 13485 Certified and FDA registered. Learn more about our certifications.

Our contract manufacturing capabilities, focused on single-use and disposable medical devices, include innovative autoinjector platforms designed for subcutaneous or intramuscular injection. These platforms can be customized to your drug formulation.