Precision Surgical Device Engineering to Support Rapid Commercialization

August 2, 2024

Join us at DCAT, New York March 23-26, 2026

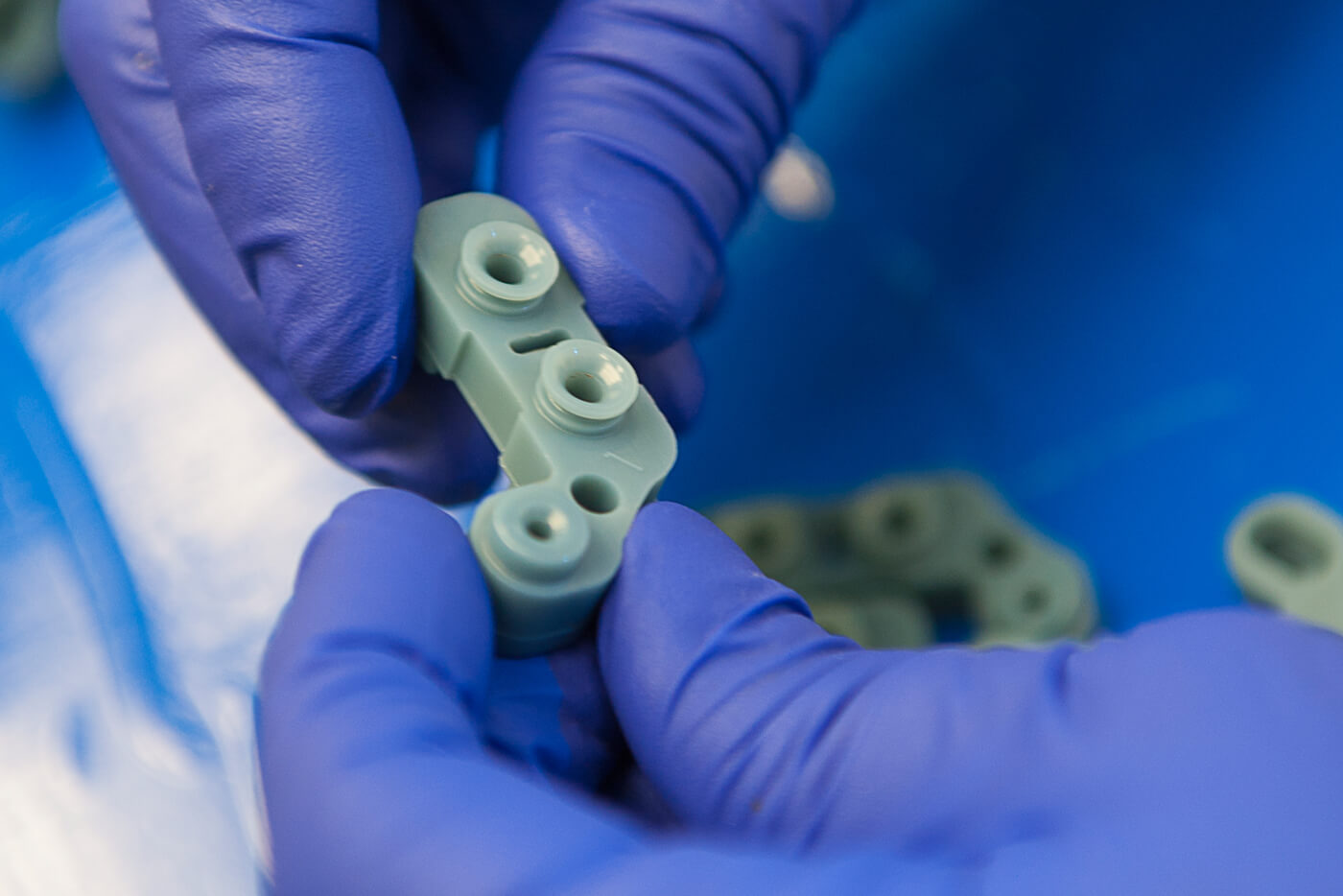

Every single-use medical device we manufacture begins with the science of precision thermoplastic molding. SMC Ltd. specializes in molding complex geometries and tight-tolerance components used in drug-delivery systems, diagnostics, and other healthcare applications.

From concept through commercial production, our vertically integrated approach combines advanced molding technology, cleanroom environments, and automation to deliver consistent, compliant, and scalable solutions across global facilities.

All thermoplastic processes are validated to IQ/OQ/PQ protocols, ensuring repeatability and full regulatory compliance. Through scientific molding practices, we maintain optimal process control and part integrity—producing premium components with every press cycle.

With device applications, cosmetics are often as critical as dimensions. Upfront, we will work with you to establish expectations of parting lines, witness lines, ejector locations, gate locations and knit line concerns.

Most often, the molded part is just the start of the manufacturing process. Following the molding process might be a pad printed or laser-marked logo press side, or the component might go directly into an assembly or sub-assembly. With our knowledge and planning of the assembly process, we build into the molding operation any needed part orientation upon ejection from the mold.

Our thermoplastic molding processes are designed for the tight tolerances, cleanliness, and regulatory standards required in medical device manufacturing.

From early material selection through automated assembly and full-scale production, SMC integrates every phase of thermoplastic manufacturing. Our vertically aligned process ensures consistency, compliance, and speed to market, reducing transfer risk while maintaining the highest standards of quality and precision.

Our contract manufacturing capabilities, focused on single-use and disposable medical devices, include innovative autoinjector platforms designed for subcutaneous or intramuscular injection. These platforms can be customized to your drug formulation.